While other mechanical seals will fail after a few seconds of dry running this seal will not. It can run dry for 20 minutes without damage. This makes a critical failure fixable.

Fabricated with a KFR coating applied to the silicon carbide face, which produces a coefficient of kinetic friction between .05 and .1 when dry. This reduces the temperature increase by 100F in the faces and extends the life of the seal up to 20 minutes when faced with dry running conditions. The KFR coating increases to hardness of the silicon carbide face, to 50 GPa (2X the hardness of silicon carbide at 35 GPa.) This makes the product resistant to abrasive sand-like particles in the liquid being transferred.

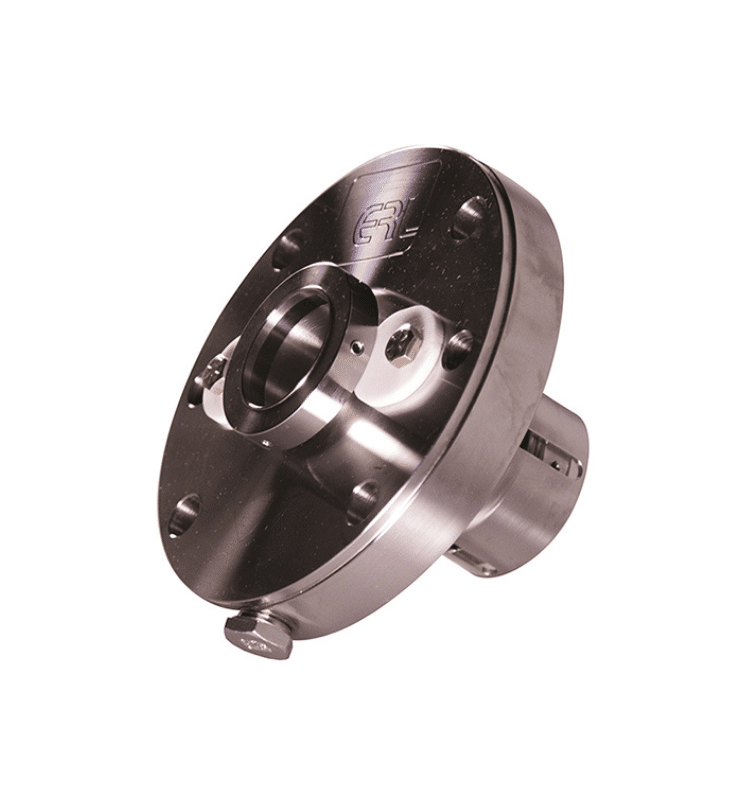

Dry Running Capability

Most mechanical seals will fail after only a few seconds of dry running. The ERL Mechanical Seal with KFR technology allows tankerman to run the pump dry for up to 20 minutes without damage. This is a revolutionary feature. Small mistakes by tankerman resulted in failed seals at the dock when reliability is the most critical. This is no longer an issue with ERL mechanical seal with KFR

The Issue With Most Mechanical Seals

Most mechanical seals have a carbon graphite face and a silicon carbide face. These two material combine to have a coefficient of Kinetic friction between .16 and .20 when dry. This high friction coefficient combined with the preloaded faces causes the face temperature to increase rapidly. When the rotational face increase temperature rapidly it expands inside the stainless steel ring causes thermal distortion and cracking that leads to failure and leakage. This failure will occur in mere seconds.

Kinetic Friction Reduction (KFR) Coating

The ERL mechanical seal has a KFR coating applied to the silicon carbide face. This coating produces a coefficient of kinetic friction between .05 and .1 when dry. This reduces the temperature increase by 100F in the faces and extends the life of the seal up to 20 minutes when faced with dry running conditions.

Increased Hardness

The ERL mechanical seal KFR coating also increases the hardness of the silicon carbide face. The result is a face that is wear resistant to cargo such as crude oil that contain abrasive sand like particles. The hardness of the KFR coating is 50 GPa. This is 2X the hardness of silicon carbide at 25 GPa.