Did you know that mechanical seals have been in existence for more than 100 years? George J. Cook created the mechanical seal in 1923 under Patent #1545080.

A mechanical seal is a piece of equipment that provides a seal on rotating equipment at a shaft’s entry or exit point. It’s typically used to help stop the leakage of one high-pressure fluid into a lower-pressure liquid.

Mechanical seals are employed in virtually every industrial operation. Automobiles, ships, rockets, industrial pumps, compressors, home pools, and dishwashers are many applications.

Do you know why mechanical seals are used to keep fluids in a vessel contained? Do you want to see how these seals function? Then, continue reading to learn the fundamentals of mechanical sealing.

What Are Mechanical Seals?

A mechanical seal contains fluid within a vessel by a rotating shaft passing through a fixed housing. Or, also, by the housing revolving around the shaft. For example, mechanical seals are typically used in pumps.

The challenge in sealing a pump is to enable a rotating shaft to gain entry into the ‘wet’ area of the pump. At the same time preventing high quantities of pressurized fluid from escaping.

You need a seal between both the pump housing and the shaft to contain the process pressure and withstand the shaft’s rotational friction.

There are several kinds of mechanical seals to choose from. These depend on the type of pump and the processing method. Each seal option has a distinct design and characteristics suitable for a particular application.

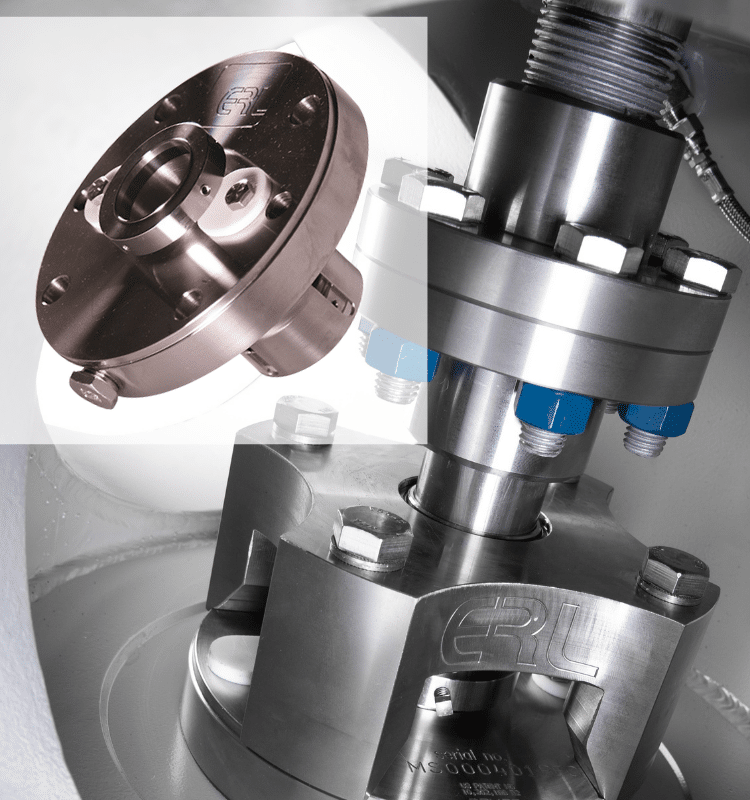

Mechanical Seal Components

But what makes up a mechanical seal? The majority of mechanical seals are composed of five pieces:

- Revolving primary face which closes against the static main sealing element

- The static main face is fastened to the pump’s stationary housing and seals against the revolving primary sealing element

- Mechanical loading components can include single, multiple, wave springs or metal bellows

- The secondary seal adjusts for any shaft motion that may harm the seal faces

- Drive mechanisms move the rotating main seal face

These are essentially the five parts of all mechanical seals.

What Are the Types of Mechanical Seals?

You can have seals made to order to meet a broad range of applications. However, some seals fit the needs of specific applications. You can classify most seals into one of the following main types of component mechanical seals.

Mechanical Wave Spring Seals

You use mechanical wave spring seals in the medicinal, dairy, breweries, and food processing industries. You use stationaries with anti-rotation pins in high viscosity media, and you mount them with grub screws. Some are designed to work in shallow, constrained seal housings.

Water Pump Seals

Water pump seals work in wet conditions. Applications using water pump seals such as:

- Irrigation systems

- Heating systems

- Swimming pools

- Bath spas and outdoor spas

To make sure that water pump seals work efficiently, you need to make sure they’re made of high-quality materials like rubber or metal.

Mechanical Metal Bellows Seals

The mechanical metal bellows seals are compact, adaptable, and exceptionally reliable in various applications. Recommended for solids-containing media and are commonly used in pumps, mixers, and compressors, among other applications.

Mechanical Diaphragm Seals

You use diaphragm seals in many industrial activities, like compressors, agitators, pumps, mixers, and other things with rotating equipment with a shaft. This is because the diaphragm in the rotating head rotary seal is on the shaft, so it doesn’t matter how the shaft turns.

Balanced Diaphragm Seals

These seals are similar in function to diaphragm seals, but they are additionally hydraulically balanced to minimize friction and heat at the sealing surface.

Mechanical Conical Seals

This is a very versatile mechanical seal. They are sturdy and durable and come in a variety of materials. However, these seals require rotation and come with left or right-hand springs.

Mechanical Parallel Seals

Part of the heavy-duty series. They can be offered with left- or right-handed wound springs and various face to seal procedures. They are used in water pumps, particularly in marine pumps, textiles, and refrigeration compressors.

Multi-Spring or Double Mechanical Seals

These seals are commonly utilized in the chemical sector for difficult activities because of their proven effectiveness—for example, corrosive processing fluids.

The mechanical seals must be of the highest quality. It is also essential to choose the correct seal based on the purpose of the product.

Why Are Mechanical Seals Important?

A mechanical seal is very important in pumps or other machines. Mechanical seals are meant to keep the fluid, whether it be water or oil, used by a device from spilling out into:

- The electrical system, which could cause it to break down

- The environment

Improved mechanical seals will prevent liquid leakage and increase machine efficiency, resulting in energy savings and less environmental contamination.

Furthermore, in some cases, rotary machines handle content that, if leaked, can result in a dangerous accident and sometimes result in environmental damage. As a result, mechanical seals must be highly reliable through manufacturing supported by solid seal technology engineering expertise.

A Minor Leak Can Sink a Large Ship!

Understanding the many mechanical seals and their components is only the start. When determining the seal type to use, it is vital to consider the purpose, installation, and operation along with leakage restrictions of the system. This critical decision has an impact on the whole system’s dependability.

A properly selected seal for the job will help minimize environmental contamination while also saving money through increased system performance, longer lifespan, and improved machine safety.

Are you looking for a marine mechanical seal or other products? Then why not download our marine product catalog? Our engineers work closely with our clients to produce products that address unique needs or challenges.