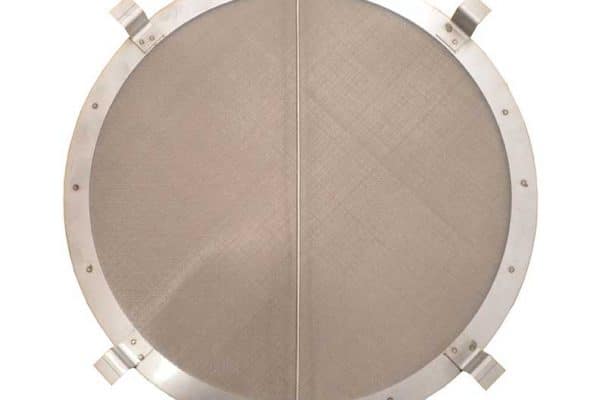

Protected Flame Screen Vent

Vent Stack

Deepwell Vertical Turbine Tank Barge Pump 10LS, 11LS, 12LS

Built to require less fuel and time to transfer liquid. This customizable product can accommodate power levels from 60HP to 300 HP, depending on pump head size. 10LS, 11LS, and 12LS pump heads can fit different-sized discharge flanges, making it possible to increase pump capacity without installing new piping. Specially constructed vertically to ensure properRead More >

Articulated Tug Barge Pump 10LS, 11LS, 12LS

Deepwell Vertical Turbine Stainless Steel Tank Barge Pump 12LS

Built to save money and time when transferring liquid. This customizable product can accommodate power levels from 170HP to 300 HP, depending on pump head size. This is accomplished by trimming the impellers to suit your application. The 12LS pump head can fit different-sized discharge flanges, making it possible to increase pump capacity without installingRead More >

Offshore Ballast Water Vertical Pump 102LS, 11LS, 12LS

This single-stage vertical pump is specifically designed for ballast water applications, with required power levels of 75HP to 100HP. Available with 11LS, 12LS, and 13LS pump heads which can fit 8”, 10”, or 12” flanges, respectively. Designed to match with existing pumping systems. We utilize stainless steel on all castings—pump heads and outer columns—for longerRead More >

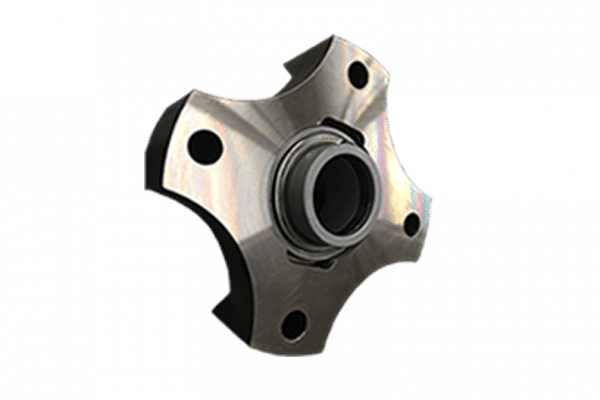

Recovery Mechanical Seal

Most mechanical seals fail at multiple points. Designed with one set of carbon faces separating liquid from atmosphere, leaks are bound to happen. Saving money with these cheaper products isn’t the best idea! ERL recovery seals add a barrier in the form a second level of sealing. No leakage is required to make this sealRead More >

Recovery Mechanical Seal with Kinetic Friction Reduction (KFR)

While other mechanical seals will fail after a few seconds of dry running this seal will not. It can run dry for 20 minutes without damage. This makes a critical failure fixable. Fabricated with a KFR coating applied to the silicon carbide face, which produces a coefficient of kinetic friction between .05 and .1 whenRead More >